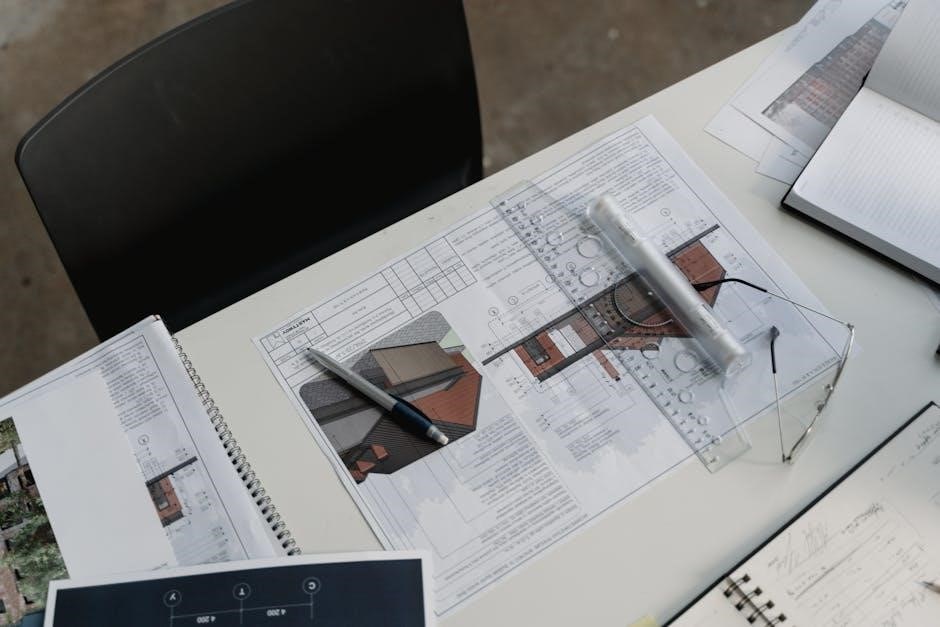

hvac layout plan pdf

An HVAC layout plan is a detailed blueprint illustrating the placement of heating, ventilation, and air conditioning components within a building. It ensures efficient system installation and maintenance, often provided in PDF format for clarity and accessibility.

What is an HVAC Layout Plan?

An HVAC layout plan is a detailed visual representation of a building’s heating, ventilation, and air conditioning system. It outlines the placement of equipment, ductwork, and controls, ensuring efficient installation and operation. The plan is often provided in PDF format for clarity and ease of access. It includes components like air conditioning units, duct layouts, and thermostats, as well as symbols and abbreviations to identify system parts. This plan is crucial for understanding how HVAC systems function and ensuring they meet building requirements and standards. By providing a clear roadmap, it helps technicians and engineers design, install, and maintain systems effectively. A well-drafted HVAC layout plan is essential for achieving optimal performance, energy efficiency, and compliance with building codes.

Importance of Layout Plans in HVAC Design

Layout plans are critical in HVAC design as they provide a clear roadmap for system installation and operation. They ensure that all components, such as equipment, ductwork, and controls, are correctly positioned for optimal performance. A well-designed layout plan helps prevent installation errors, reduces costs, and minimizes future maintenance issues. It also ensures compliance with building codes and standards, which is essential for safety and efficiency. By visualizing the HVAC system’s layout, engineers can identify potential issues early, streamline the installation process, and ensure the system meets the building’s specific needs. Additionally, layout plans facilitate effective communication among stakeholders, ensuring everyone involved understands the system’s design and requirements. This ultimately leads to a more efficient and reliable HVAC system, enhancing overall building comfort and energy efficiency.

Components of an HVAC Layout Plan

An HVAC layout plan includes detailed drawings of equipment, ductwork, thermostats, and control systems. It also features symbols, abbreviations, and legends to identify components and their specifications clearly.

Equipment Included

An HVAC layout plan details the placement and specifications of all system components, including air conditioning units, ductable units, fans, and thermostats. It also outlines refrigerant pipe connections, filters, and coils. The plan specifies equipment capacities, such as 2.5HP for FCUs, ensuring precise installation. Control systems and sensors, like CO sensors, are marked for proper functionality. Equipment schedules and abbreviations are included to streamline interpretation. Ductwork layouts show supply and return paths, ensuring efficient airflow. The plan also locates mechanical rooms and generator areas. By visualizing the entire system, it aids in maintaining optimal heating, cooling, and ventilation performance while complying with building standards and codes.

Ductwork and Ventilation Systems

Ductwork and ventilation systems are central to HVAC layout plans, ensuring efficient airflow throughout a building. These plans detail the layout of supply and return ducts, including their sizes and connections. Ventilation systems are designed to maintain air quality by introducing fresh air and exhausting stale air, often through specialized components like dampers and filters. Proper duct sealing and insulation are emphasized to minimize energy losses. The plans also specify locations for diffusers, registers, and grilles, ensuring even air distribution. Additionally, ventilation shafts and makeup air units are included to meet building occupancy requirements. These designs are typically scaled for accuracy and exported as PDFs, making them accessible for installation and maintenance. By optimizing ductwork and ventilation, HVAC systems achieve better performance and energy efficiency, aligning with modern building codes and sustainability goals.

Thermostats and Control Systems

Thermostats and control systems are essential components of HVAC layout plans, enabling precise temperature regulation and system automation. These systems are strategically placed to monitor and control heating, cooling, and ventilation operations. Modern thermostats, including smart devices, allow for remote monitoring and energy-saving features. Control systems integrate sensors, timers, and programmable logic controllers to optimize performance. The layout plan details wiring diagrams, sensor locations, and the integration of thermostats with ductwork, dampers, and valves. Proper placement ensures accurate temperature sensing and efficient system response. Advanced control systems also support zoning, allowing different areas within a building to have independent climate settings. By incorporating these elements, HVAC systems achieve improved comfort, energy efficiency, and operational reliability, aligning with both user needs and energy conservation standards.

Symbols and Abbreviations

Symbols and abbreviations are critical in HVAC layout plans for clear communication. Standardized symbols represent components like ducts, vents, and equipment, ensuring consistency across designs. Abbreviations such as “AHU” for Air Handling Unit and “FCU” for Fan Coil Unit simplify notation. These elements are often included in legends or keys within the plan, allowing easy identification of system parts. Proper use ensures that installers and maintainers can interpret the layout accurately, reducing errors. Symbols also highlight airflow directions, while abbreviations streamline complex terminology. Consistent use across plans enhances readability and professionalism, making it easier for teams to collaborate effectively. By standardizing these elements, HVAC plans become universally understandable, facilitating efficient system installation and operation.

Designing an HVAC Layout Plan

Designing an HVAC layout plan involves creating detailed blueprints for system installation, ensuring efficiency and compliance with codes. It typically includes equipment placement, ductwork, and control systems, often provided in PDF format for clarity.

Building Analysis

Building analysis is a critical step in designing an HVAC layout plan, involving the evaluation of a structure’s heating and cooling requirements. This process considers factors such as the building’s orientation, insulation, window placement, and occupancy patterns to determine the optimal system size and configuration. By analyzing these elements, HVAC engineers can ensure that the system meets the specific needs of the space, improving energy efficiency and occupant comfort. The analysis also helps identify potential challenges, such as heat loss or gain, and informs decisions about equipment placement and ductwork routing. Accurate building analysis ensures the HVAC system operates effectively, balancing performance and cost efficiency.

Load Calculations

Load calculations are essential for determining the heating and cooling demands of a building, ensuring the HVAC system is appropriately sized. These calculations consider factors like insulation, window size, occupancy, and internal heat sources to estimate the total load. Accurate load calculations prevent oversizing, which can increase costs and reduce efficiency. They also help in selecting the right equipment and designing the ductwork layout. By analyzing these loads, engineers can create an HVAC layout plan that balances performance, energy efficiency, and comfort. Detailed load calculations are typically included in the HVAC plan, providing a clear guide for installation and system operation.

System Selection

System selection is a critical step in creating an HVAC layout plan, ensuring the chosen equipment meets the building’s specific needs. Factors such as space constraints, energy efficiency, and budget are evaluated to determine the most suitable HVAC system. Common systems include split units, ductable units, and variable refrigerant flow (VRF) systems. Each option has unique benefits, such as energy savings or installation flexibility. Proper system selection ensures optimal performance and minimizes operational costs. The HVAC layout plan PDF often includes details about the selected equipment, such as model numbers, capacities, and installation locations. This information guides installers and maintenance personnel, ensuring the system operates as intended. Accurate system selection is vital for achieving comfort, efficiency, and long-term reliability in any building.

Software Tools for Design

Modern HVAC layout plans rely on specialized software tools to streamline the design process. Programs like AutoCAD, Revit, and ArcSite enable precise drafting of HVAC systems, including ductwork, equipment placement, and controls. These tools offer features such as 2D and 3D modeling, ensuring accurate representations of the system layout. They also facilitate the creation of detailed schedules, legends, and symbols essential for interpreting the plan. Additionally, software tools allow for easy exporting of designs into PDF formats, making it simple to share and review plans with stakeholders. By utilizing these tools, designers can ensure compliance with industry standards and optimize system performance. The use of software not only enhances the efficiency of the design process but also improves the overall quality of the HVAC layout plan, leading to successful installations and maintenance.

Best Practices for Creating an HVAC Layout Plan

Ensure compliance with local codes, prioritize energy efficiency, and maintain flexibility for future modifications. Use clear labeling and include legends to enhance readability, especially in PDF formats for easy sharing and review.

Space Considerations

When designing an HVAC layout plan, space considerations are critical to ensure efficient system operation and maintenance. Properly allocate space for equipment like air handling units, ductwork, and thermostats. Ensure ducts are routed to avoid obstructions and maintain adequate clearance for installation and access. Consider ceiling heights, structural elements, and accessibility for maintenance. Plan for future expansion by leaving extra space where necessary. Use vertical and horizontal areas effectively to minimize footprint and reduce costs. Ensure that equipment placement does not interfere with other building systems or occupant comfort. Referencing PDF templates can help visualize and optimize space usage. Always verify measurements and layouts against building codes and standards to ensure compliance and functionality.

Energy Efficiency

Energy efficiency is a key focus in HVAC layout plans, aimed at reducing energy consumption and operational costs. Properly designed systems ensure optimal airflow, minimizing heat loss and maximizing cooling efficiency. Ductwork should be well-insulated and sealed to prevent leaks, while thermostats and control systems can regulate energy use effectively. Consider zoning systems to tailor heating and cooling to specific areas, reducing unnecessary energy expenditure. Equipment selection should prioritize high-efficiency units, and layouts should facilitate natural ventilation where possible. PDF plans often include energy-saving strategies and compliance with green building standards. By integrating smart technologies and optimizing system design, HVAC layouts can significantly lower energy consumption while maintaining comfort levels. Regular maintenance and upgrades, as detailed in PDF guides, further enhance long-term energy efficiency.

Flexibility and Scalability

Flexibility and scalability are crucial in HVAC layout plans to accommodate future changes or building expansions. Designs should allow for modifications without major overhauls, ensuring adaptability to evolving needs. Ductwork and equipment placement should be planned to facilitate easy upgrades or additions, such as new zones or increased capacity. Modular systems, detailed in PDF layouts, offer ease of expansion and customization. Thermostats and controls can be programmed to adjust to varying conditions, enhancing system adaptability. Proper spacing in mechanical rooms and accessible pathways for ducts and pipes support scalability. By integrating these elements, HVAC systems remain efficient and responsive to changing requirements, ensuring long-term functionality and cost-effectiveness. PDF plans often highlight these considerations to guide installers and engineers in creating adaptable systems.

Compliance with Codes and Standards

Ensuring compliance with local, national, and international codes and standards is essential in HVAC layout plans. These regulations dictate safety, efficiency, and environmental requirements, ensuring systems operate within legal frameworks. PDF plans must include details that verify adherence to standards like ASHRAE guidelines, building codes, and energy efficiency regulations. Proper documentation, such as equipment specifications and installation methods, is critical for inspections and approvals. Non-compliance can result in legal issues, increased costs, and potential system failures. By incorporating compliant designs, HVAC systems meet safety standards, reduce environmental impact, and optimize performance. Architects and engineers rely on these PDF layouts to demonstrate adherence to codes, streamlining the approval process and ensuring reliable system operation.

HVAC layout plans are crucial for efficient system installation and maintenance. Available in PDF format, they ensure compliance with standards and provide clear designs for optimal heating, ventilation, and cooling operation.